Golf/Tennis Ball Sorting Robot

As a part of the Design & Manufacturing Lab course at the University of Florida, I was challenged to design and manufacture a robot capable of sorting one bucket of 5 golf balls and 5 tennis balls into two separate buckets. The project was divided into four design reports, each taking roughly 20-30 hours per week to complete.

Design Report #1

I was tasked with creating scale hand-drawn sketches of my concept, followed by a CAD model to estimate center of mass and overall weight values. Parameters for this design included staying below a $50 budget (not including motors nor drivers), size restraints, and theoretical manufacturing time constraints.

Design Report #2

After completing my individual design, I was paired with three other students to comparably determine the best design for the project. In order to do so, the group analyzed each design using decision matrices and tested prototypes when necessary

Decision matrix comparing some of the common characteristics of each design

Testing different arm designs in terms of ball/bucket security

Calculating different centers of mass for different arm and bucket combinations

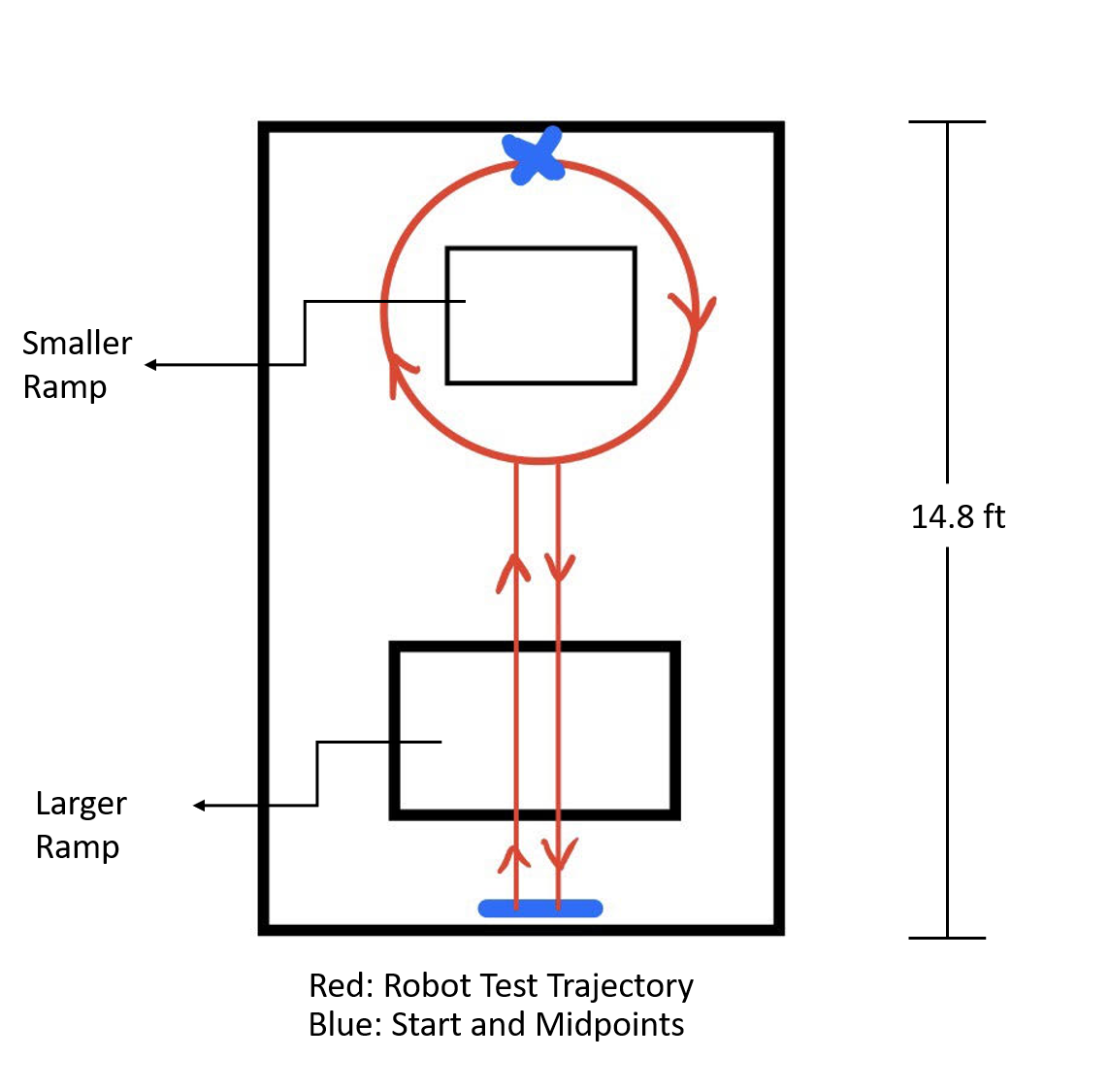

Projected trajectory based on mobile platform design width and motor torque

In lab testing to determine most efficient combination of motor torque and wheel size

Design Report #3

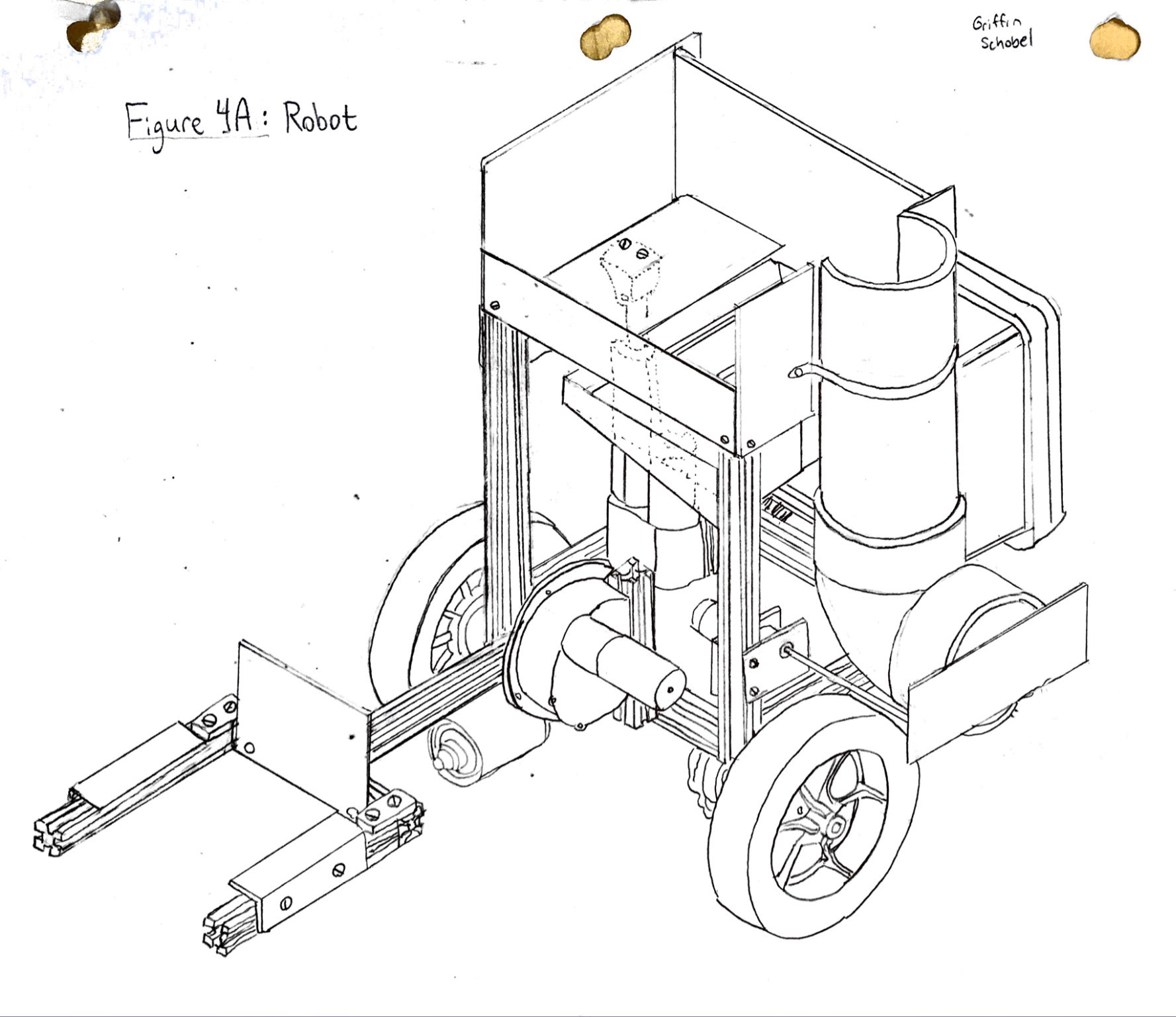

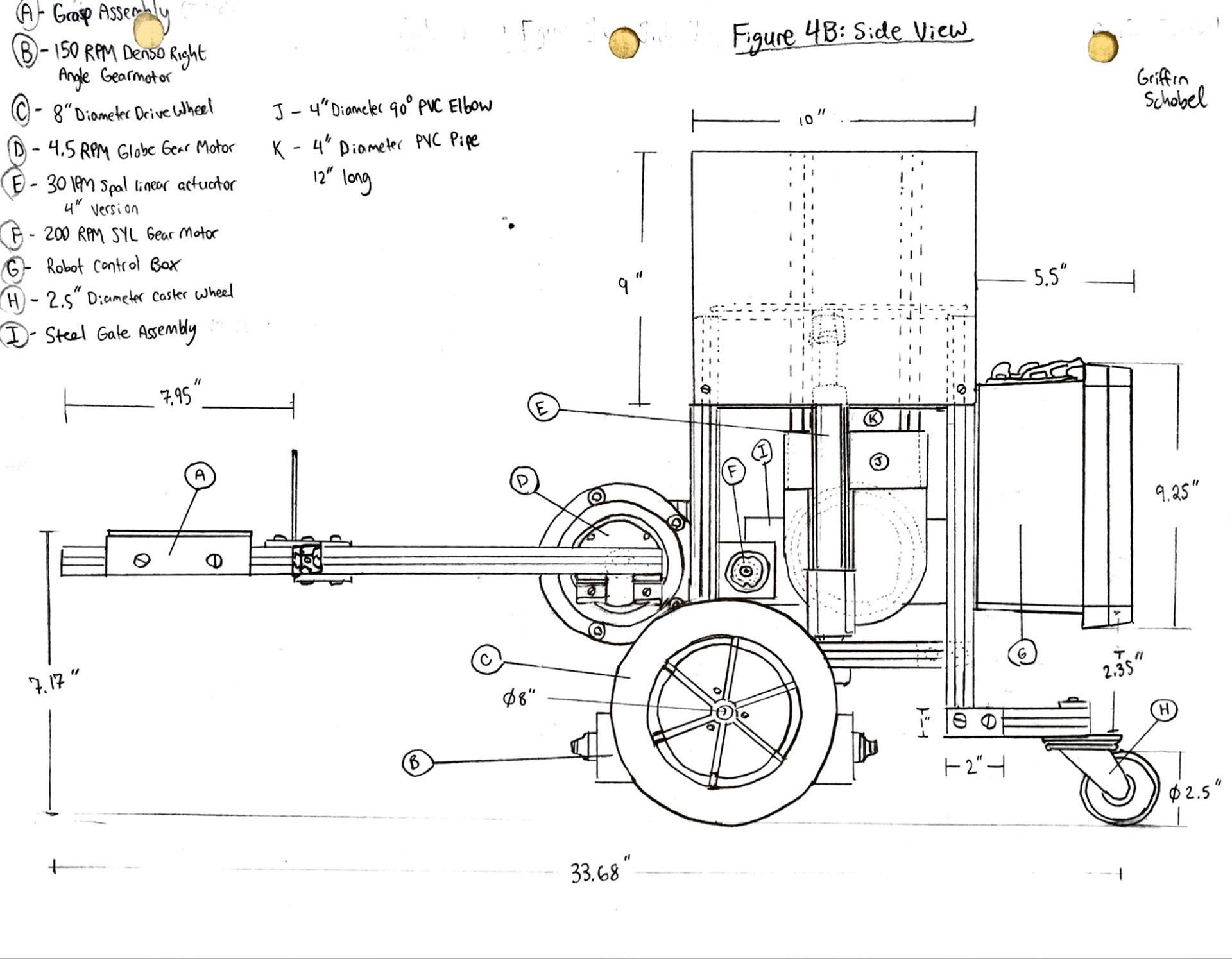

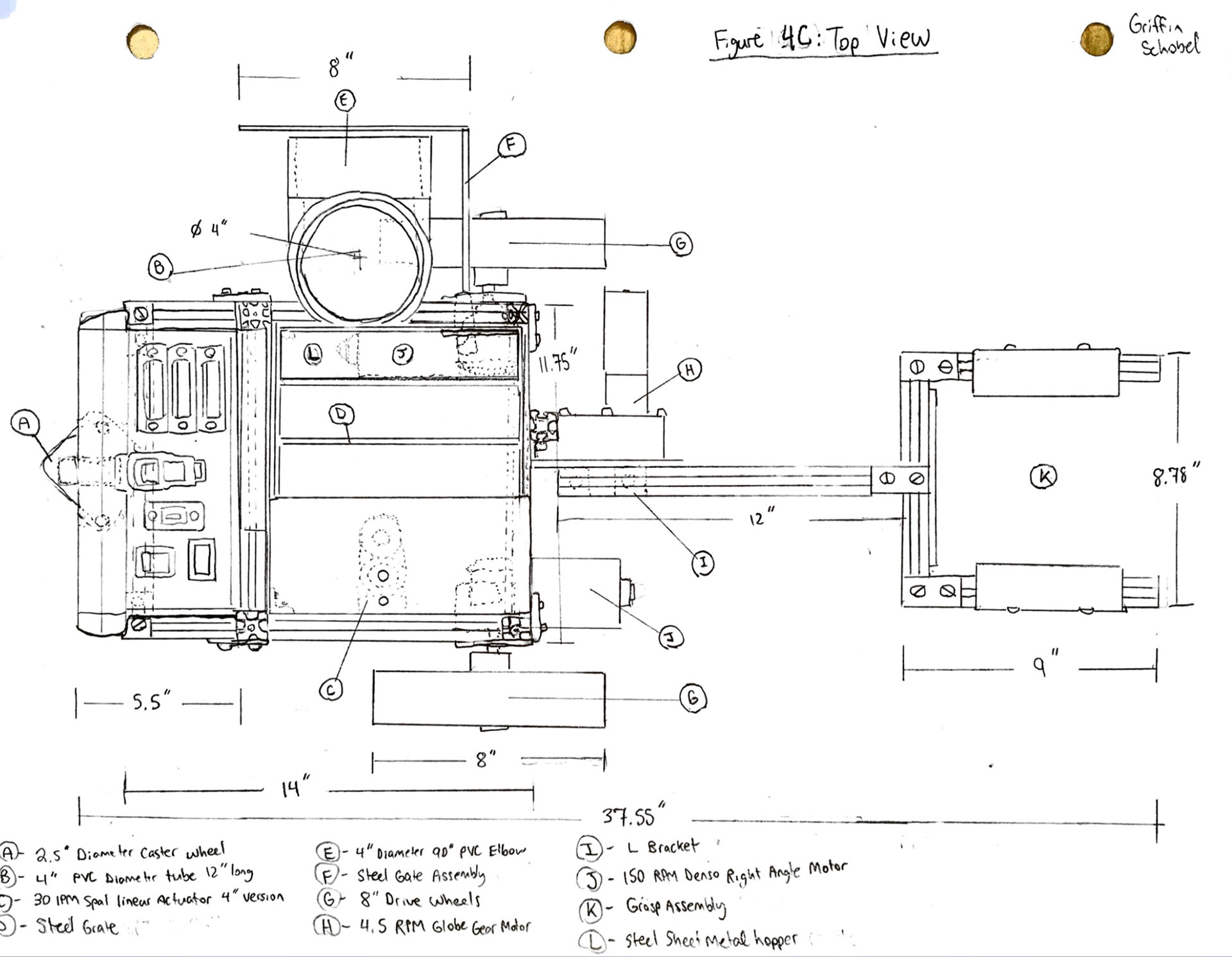

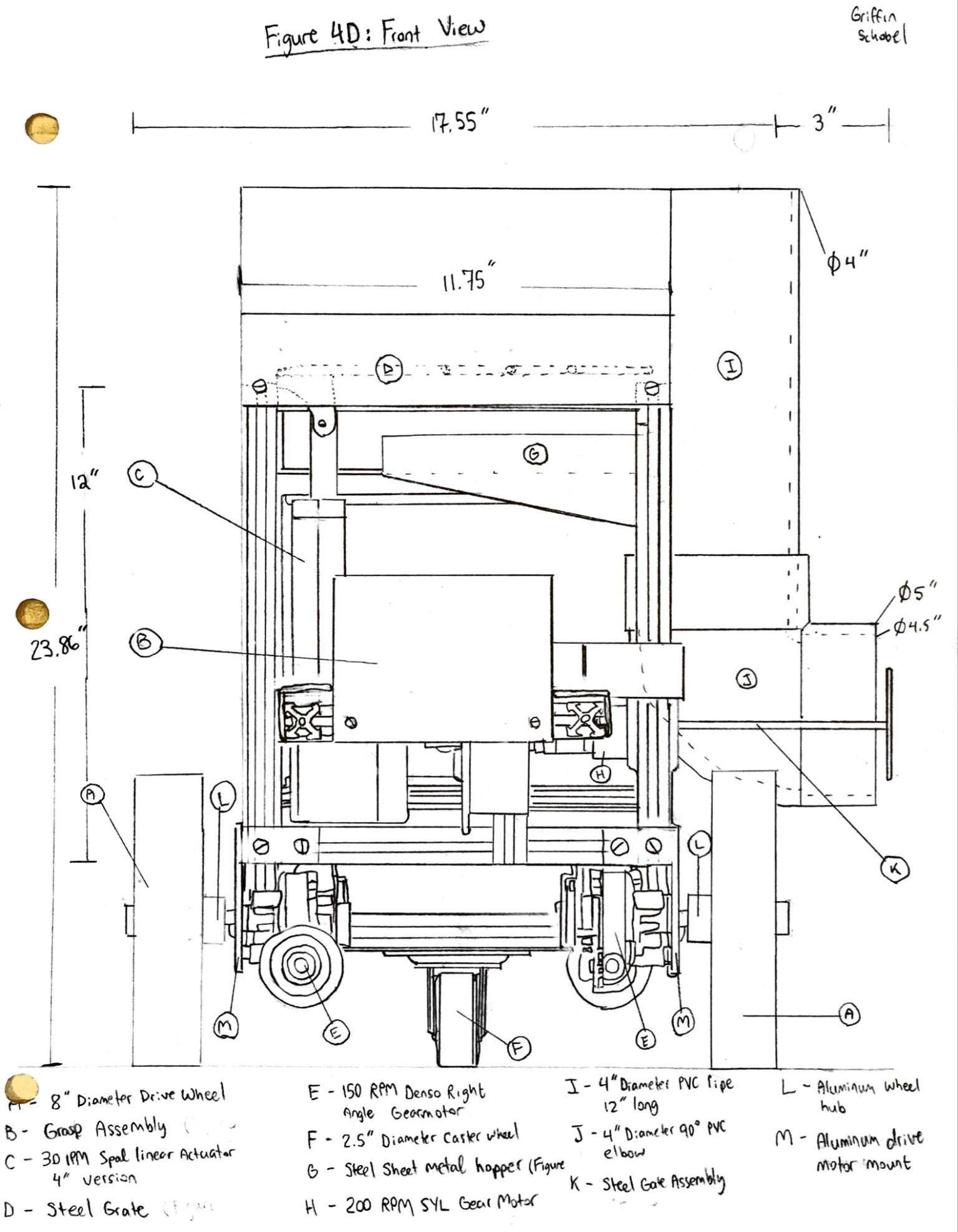

This design report consisted of creating a final CAD model for the new design based on all of the testing from Design Report #2. Along with the CAD model, we were required to create detailed part and assembly drawings for the entire design.

Full CAD model of the final design

Top view

Front View

Close-up on gate assembly

Design Report #4

This design report consisted of manufacturing our design, submitting engineering change notices, and competing with other student groups to collect/sort the most balls as quickly and efficiently as possible. This phase was great because it provided us with hands-on manufacturing experience using CNC mills, lathes, CNC waterjets, bandsaws, and TIG welding.

A special thanks to my partners Darshan Patel, Matthew Everhart, and JJ Pennington for putting countless hours into this design course. Another special thanks to our helpful teaching assistant Hunter Hopkins for guiding us through manufacturing and design.